Article

How the fusion of the physical and digital world will power the next productivity revolution

Published

6 December 2023

What is Supply Chain 4.0?

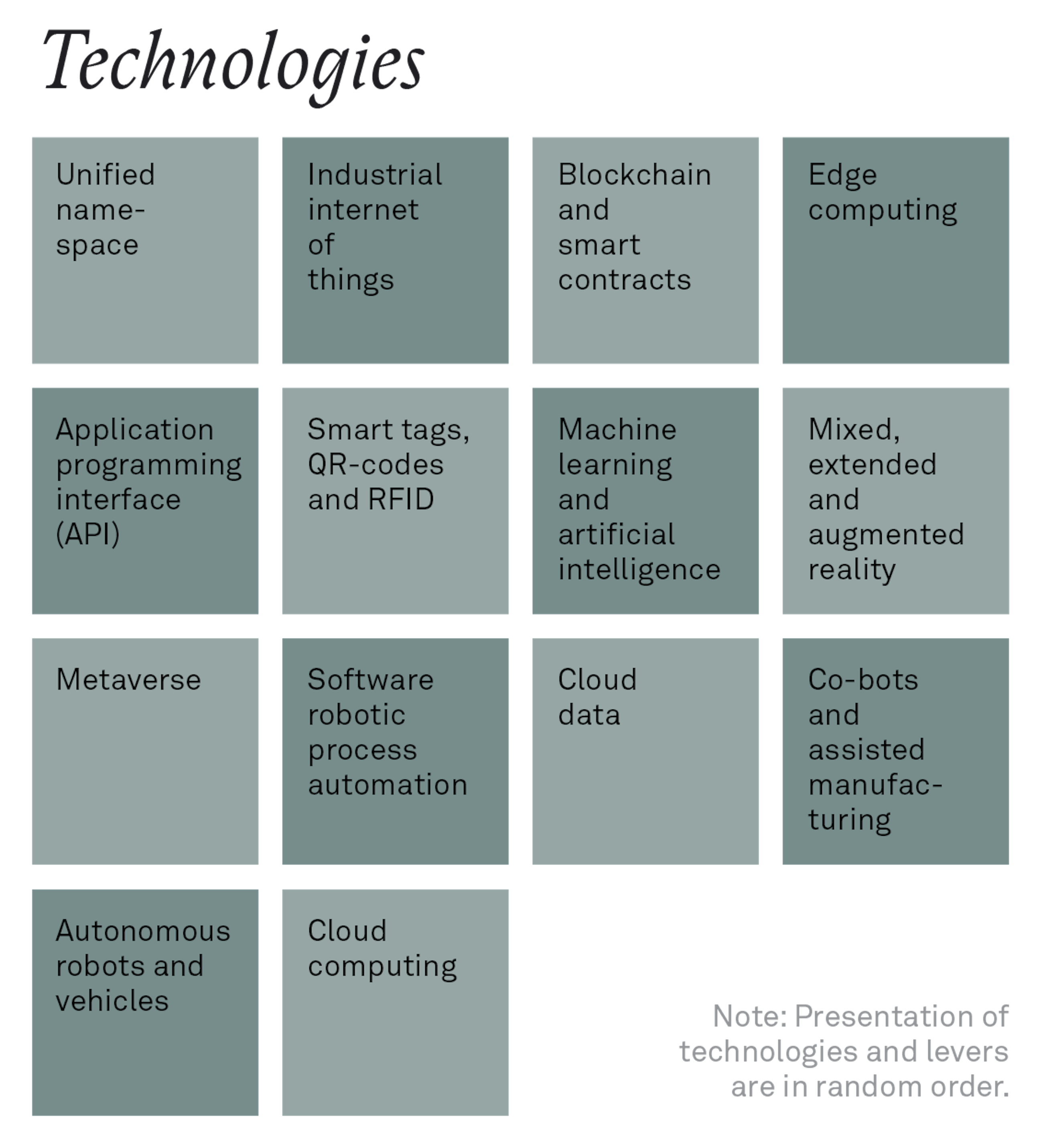

Artificial intelligence, big data, internet of things, blockchain, software robots, autonomous vehicles, cloud and edge computing, 3-D printing, augmented, mixed and virtual reality, digital twins, wearable technologies, collaborative robots and predictive maintenance. These are just some examples of (relatively) new technologies. And while they may have more things in common, one is that they combine the digital and physical world, making them part of the fourth Industrial Revolution and key components of supply chain 4.0.

Supply chain 4.0 (SC 4.0) refers to the incorporation of digital technologies in various industries and business processes in a way in which the physical and digital world is blending, creating new business models and transforming traditional industries. As with other industrial revolutions, it is a fundamental shift in how goods and services are produced, delivered and consumed, this time enabled by integrating physical and digital systems into so-called cyber-physical systems.

Supply chain 4.0 applies the technologies and vision of Industry 4.0 to the entire supply chain, increasing visibility, agility and responsiveness and, in turn, improving operational efficiency.

Industry 4.0 had its first public mention in a 2011 strategy of the German industry sector. This had the purpose of describing the digitalisation of production processes based on devices autonomously communicating with each other along the value chain and was based on a vision of “the smart factory of the future” where digital computer-driven systems monitor physical processes, create a virtual copy of the physical world and make decentralised decisions based on a self-organising mechanism.

Since then, new technologies have emerged, and the vision of the smart factory has, in many fora, expanded beyond that of its original intent to broader industrial usage, one of which is supply chain 4.0. In this interpretation, digital technologies will fuse with physical operations from suppliers over manufacturing, warehouse and delivery to end consumers.

What does it take for a supply chain to be “4.0”?

The first Industrial Revolution saw the invention of an abundance of machines for producing textiles, the first machine tools, iron making at a greater scale and the steam power engine. While all of these inventions are associated with the first Industrial Revolution, no one machine encapsulated the period.

Similarly, supply chain 4.0 is characterised by new ways of working and a number of inventions, some of which are united by a common technological lever and used to boost productivity at various ends of the supply chain. This means that any supply chain does not simply become a “version 4.0” by adopting a single technology in one link of the chain.

To be more specific, a supply chain 4.0 needs to satisfy two requirements:

#1: Adopt cyber-physical technologies (see later in this article) to continuously raise improvement to jointly add to the pool of productivity gains.

#2: Perform integrated supply chain management (not an SAP module), where information is shared and available to all entities in the network, even outside of the supply chain of the company.

In the following, we will be investigating in greater detail what these two points mean and give a number of examples.

Industrial revolutions

Intermezzo

The flow of an order in a Supply Chain 4.0

ORDER SUBMITTED

Customers submit orders on a website, via an API or on an app, incl. quantity and personalised specifications. |

PLANNING

After submission, the order is incorporated into the continuous E2E planning flow, which uses machine learning to enhance the incorporated artificial intelligence algorithm that subsegments the supply chain. In doing this, the requirements throughout the supply chain are determined, and information is gathered about available resources, balancing requirements and resources to determine planned capabilities and gaps in demand. |

ORDER ORCHESTRATION

The order is transmitted to a Central Order Management System (COMS), which continuously processes and routes incoming orders to the appropriate nodes of the supply chain |

SUPPLY CHAIN COORDINATION

The COMS assesses the order’s specifications, taking into account factors such as product availability, manufacturing capacity and logistical considerations. Drawing on the available data in the UNS, it determines that the order is to be fulfilled by a nearby factory. |

PRODUCT TRACEABILITY

| SHIPPING PREPARATION The TMS generates a shipping label, printed via WMS, and arranges for the products to be dispatched to the customer’s address. Advanced routing algorithms ensured the most efficient and cost-effective transport method, considering factors such as distance, traffic and carrier availabilit. |

| PRODUCTION ORDER SCHEDULING The MES and ERP pick up the information communicated by the COMS in the UNS and direct the production line to begin manufacturing the requested products in addition to necessary resources such as raw materials and labour. | WAREHOUSE PREPARATION The WMS at the local DC picks up the information left in the UNS by the COMS. The WMS receives real-time updates about the incoming order, allowing it to optimise its inventory management and prepare for the shipment. |

CUSTOMER

Throughout the process, the customer receives personalised notifications indicating the estimated time of arrival for the awaited products. The customer tracks the progress of the delivery in real time and is allowed to make in-flight changes according to delivery preferences |

DELIVERY At the desired address, a delivery is made by a drone or operator who verifies the customer’s identity using biometric authentication, ensuring a secure handover of the products. |

… any one supply chain doesn’t simply become a ‘version 4.0’ by adopting a single technology in one link of the chain.

The digital infrastructure enabling the vision

To enable the digital vision of supply chain 4.0, the right infrastructure must be put in place. While a traditional technology stack with point-to-point integrations is the reality in most companies, a microservice structure enables a more scalable business and ensures that future technologies can gradually be connected and applied to improve performance and services.

A microservice infrastructure is characterised by having a single source of truth – a unified namespace (UNS) – where software and services can be connected in a broker-subscriber model.

This infrastructure can be established in parallel with the existing point-to-point integrations, and a gradual phase-over method is possible, making the entry barrier significantly lower.

In total, the unified namespace enables disparate supply chain elements to draw on data generated at entirely different locations. In a traditional model, data generated on the shop floor would have to escalate through SCADA and MES before landing in the cloud.

In a UNS, all data is available in a unified way so that it appears as if it is all in one place. This makes it possible to go from a linear supply chain model, in which each step is gatekept by a planning routine depending on the data at the previous and following step, to an integrated model, in which each step in the supply chain can draw from the same pool of data.

SC 3.0 – linear supply chain

In SC 3.0, planning and execution models are linear, meaning that plans and feedback are typically only shared between two entities in the supply chain.

SC 4.0 – integrated SCM

In SC 4.0, planning and execution are integrated, and all information is shared and available to all entities in the supply chain network – even outside our span of control, e.g. suppliers.

The new technologies and productivity levers

The current Industrial Revolution is ongoing with full force, and giving an exhaustive list of the elements of SC 4.0 is, therefore, clearly impossible and, at best, only outdated to a minor degree. The below is an attempt to give a brief overview of technologies and levers that, at the time of writing, are implementable and add value if applied in supply chains where they make sense.

Ready, set go ...

Considering the rapid advancements and disruptive technologies of supply chain 4.0, organisations must carefully consider where to go from the current standpoint to ensure their long-term success.

Embracing the principles of digitalisation, connectivity and data-driven decision-making is crucial, but with the complexity and scale of transformation available, it becomes essential to have a clear road map for progress.

This leads to the question of where to start. One take on this question is simply to figure out where you are at the moment and follow up with the question of where you need to go or how an improvement can help you.

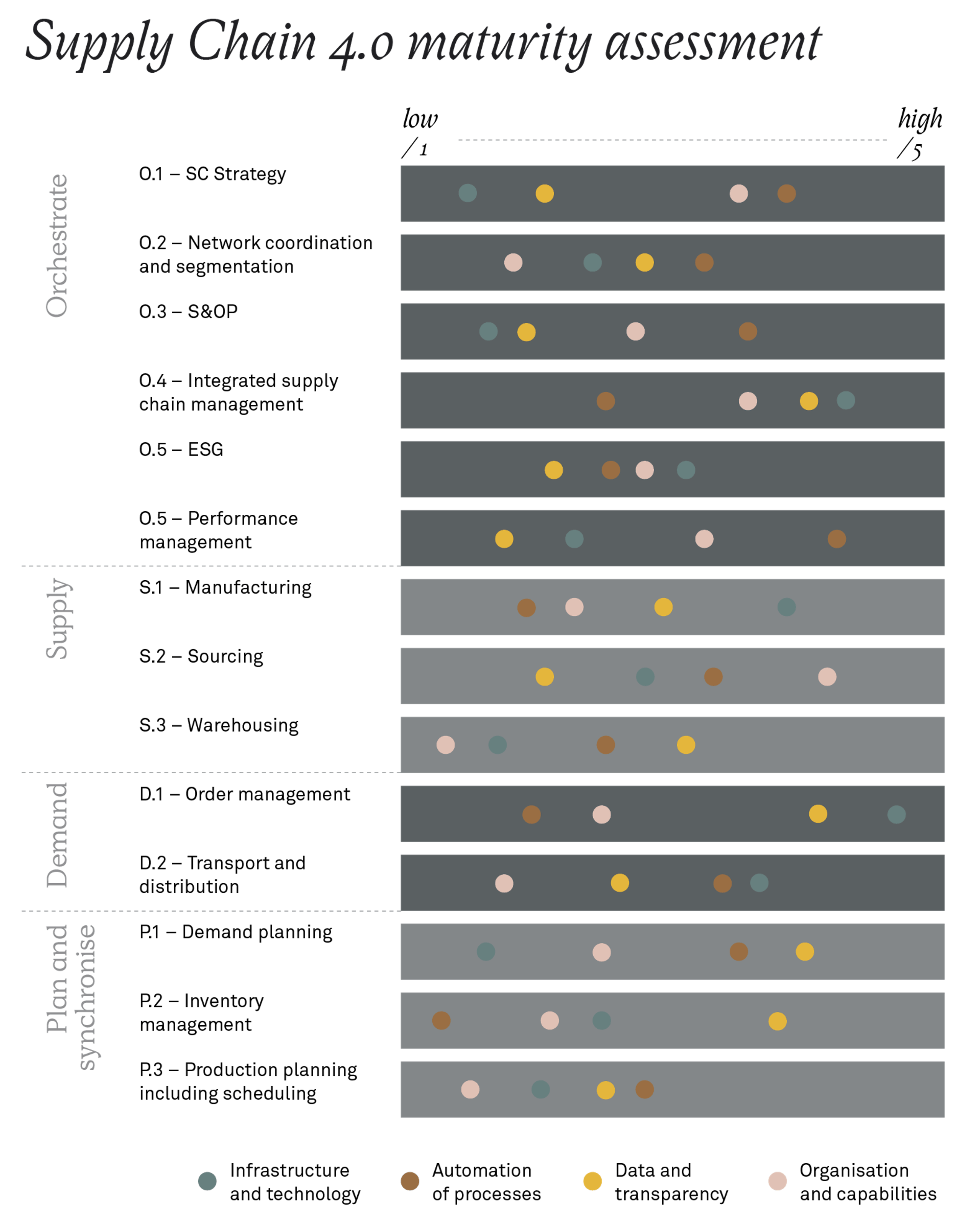

The below simple maturity assessment framework is an easy place to start, featuring four dimensions within 14 topics. This assessment can provide valuable insights into an organisation’s current state, identify areas for improvement and guide strategic decision-making.

Want to know more?0 3

0

3Related0 4

Article

Read more

Transform supply chain planning with AI

Today, most supply chain executives recognise AI’s potential to transform their supply chains – from design and operatio...Article

Read more

From export to local production

Strategic responses to a shifting US trade environment.Article

Read more

Planning with configurable products using S/4HANA PP/DS

How PP/DS works with variant configuration in SAPArticle

Read more